- Photonics & Space

Laser fusion: beyond new frontiers

In a decade, Exail has become the sole supplier of radiation resistant diagnostics optical fibers, enabling the National Ignition Facility (LLNL NIF) in the US and the Laser Megajoule (CEA LMJ) in France to reach new limits in terms of performance.

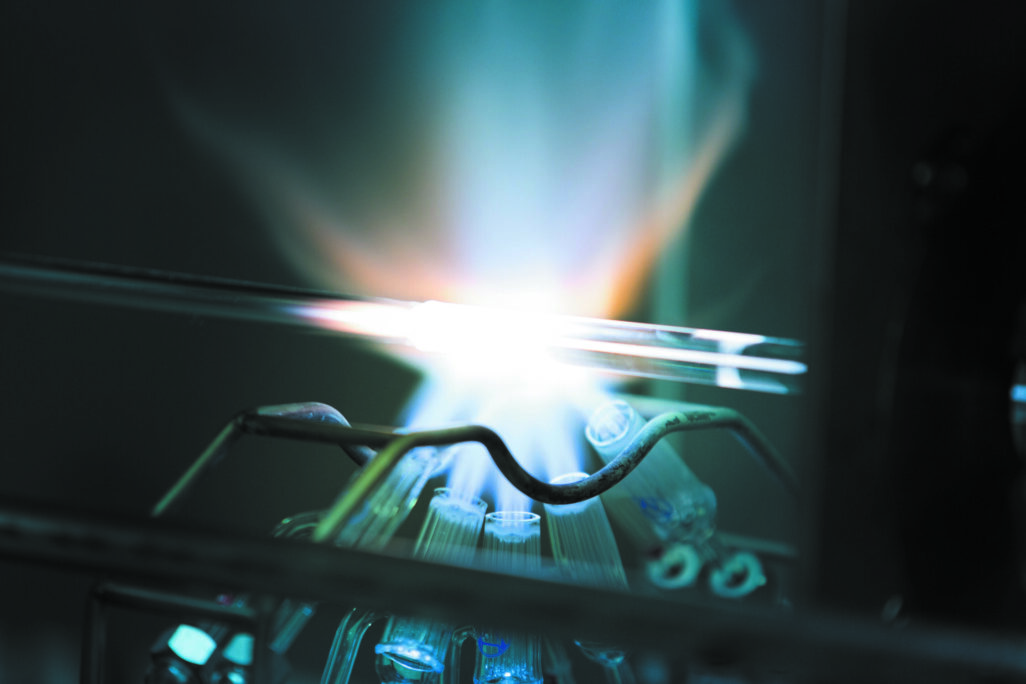

In December 2022, the team of Lawrence Livermore National Laboratory (LLNL NIF) performed the first fusion ignition experiment – with more energy released from the fusion reactions (3.15 MJ) than the laser energy (2.05 MJ) used to trigger them. France built its equivalent of the LLNL-NIF, the Megajoule Laser (CEA LMJ). Commissioned at the end of 2014, it is primarily used to ensure the safety and reliability of nuclear weapons for deterrence. Accurate diagnostics are crucial to reach thermonuclear gain fusion with high energy lasers. The teams of both facilities have had strong interactions over the years, facing similar challenges and sharing their technical knowledge and competency, in particular around diagnostics optical fibers able to resist intense levels of radiation.

The CEA LMJ and LLNL NIF are huge facilities: hundreds of pulse laser beams, with a duration of around a nanosecond, are targeted on a millimeter-sized microsystem. Once combined, the laser beams reach an ultraviolet laser energy of 1.2 MegaJoule (more than 2 MegaJoules at LLNL NIF) in a luminous flash producing hundreds of terawatts (thousand billion Watts). By accurately synchronizing the laser beams, it is possible to carry out extremely complex laser-matter interaction experiments with an incredibly high level of homogeneous compression.

The target is designed to reproduce, after having received the MegaJoule of energy, a phenomenon of the same nature as that occurring in weapons, or in the core of stars. The most complex experiments are those leading to thermonuclear gain fusion (the nuclear energy released by the fusion reactions is greater than the laser energy invested to trigger these reactions) by inertial confinement of a deuterium-tritium mixture in the micro-target. Creating and accurately controlling such extreme physical parameters also opens the doors for new physics. “We receive more and more requests from scientific researchers wanting to use our laser facility to explore laser-matter interactions” Nicolas Beck, research engineer at CEA LMJ.

The extremely accurate synchronization of the pulse laser beams is made possible by measurement diagnostics, which are specialized state-of-the-art measuring instruments collecting data from the experiment in real-time.

Exail, a unique supplier for reliable radiation resistant diagnostics optical fibers

At NIF and LMJ, an optical network is connected to the experimental chamber to recover data of the laser beams through the measurement of their energy, their temporal and their spectral characteristics. The diagnostics optical fibers used to transmit the data within the 30 m close to the target (within the concrete protection – see below schematic view) must stay operational despite the extreme conditions and at a high-speed (bandwidth is -1 ps): it must ensure that the temporal shaping of the laser beam remains unaltered, and the optical attenuation must be extremely low to assure a good transmission of the measurement data. But the most critical aspect is the resistance to radiation involved in the experiment process, that usually damages, or darkens diagnostics optical fibers.

This is where Exail expertise in specialty fibers come into play. Its radiation resistant optical fibers are able to perform reliable diagnostics up to the experiment chamber, where radiation is the most intense. They have become mandatory components for both LLNL and CEA facilities to reach new limits such as fusion ignition or thermonuclear gain fusion.

Exail diagnostics optical fibers operate up to the experiment chamber at CEA LMJ

Leveraging a decade of academic industry collaboration

Exail develops optical fibers for radiation monitoring in radiation-rich mixed environments typically present in the Megajoule class laser facilities. For the laser diagnostics, multimode optical fibers with “graded-index refractive-index profiles” have to be used, to reduce the dispersion impact on measurement quality. In classic step-index multimode optical fibers, the signal is propagated through different optical modes that travel at different speeds. Thus, the temporal information of a given signal is not preserved through propagation. This is of the utmost importance when the light is carrying diagnostics data related to a thermonuclear reaction you want to monitor. Fortunately, Graded-Index” MultiMode (MMGI) optical fiber ensures that each mode injected into the fiber reaches the diagnostic sensor at the other end at the exact same time.

Thanks to a decade of investment in R&D and research collaborations between Exail and Prof. Sylvain Girard (former researcher at CEA, now Professor at St-Etienne Univ. and co-manager of the LabH6 joint laboratory), the development of a highly specific type of optical fibers became possible. This large core diameter (400 µm) multimode fiber is highly transparent to UV light (thanks to specific treatments of the silica) in order to capture and transmit the maximum of data, while exhibiting both unique radiation-resistance and low temporal dispersion. This diagnostics fiber was designed and is now produced at the Lannion site of Exail. It was qualified and installed at CEA LMJ in summer 2019.

“Before Exail, only a laboratory had succeeded in producing graded-index fibers matching all our strict specifications, but the fibers were not radiation hardened. With Exail’s radiation resistant fibers, we can now guarantee the quality and accuracy of the data collected at any point of the experiment, in particular in the experiment chamber where radiation levels are extreme. It gives us a much clearer diagnostic of whether the experiment is conducted smoothly or not, when experiments were mostly conducted “blindly” before due to the poor information we could recover from the target” explain Nicolas Beck.

During the historic fusion ignition experiment on December 5th, 2022 at the NIF, about 1018 (a quintillion) of high-energy neutrons were released. Under this harsh environment, the UV Exail fibers used to transport the laser power signal behaved very well as no significant attenuation was observed. Gradually, the NIF obsolescent fibers were replaced with several kilometers of Exail radiation resistant UV fibers, thanks to a collaboration between Exail, CEA LMJ and LLNL NIF.

“With Exail’s radiation resistant fibers, we can now guarantee the quality and accuracy of the data collected at any point of the experiment, in particular in the experiment chamber where radiation levels are extreme.“

Towards new applications for radiation hardened fibers

After such a strong and successful collaboration around Exail’s diagnostic optical fiber in both the CEA LMJ and LLNL NIF facilities, the modulation solutions of Exail (mainly the LiNbO3 optical modulator for the pulse shaping of the laser beam), already used at CEA LMJ, are now also being qualified for use on the LLNL NIF.

According to Nicolas Beck “With the radiation resistant fiber and the modulator for the temporal shaping, you can actually consider that Exail is on the right track to deliver two key components to the main high-energy laser facilities in the world. It shows your company can deliver cutting-edge technology for the high-energy laser field. As our specifications are extremely high, it means the same technology can meet the demand of other fields, including the dosimetry in nuclear power plants.”

The R&D efforts deployed by Exail and the LabH6 joint laboratory on optical fibers for harsh environments have paved the way for new type of applications, beyond the high-energy laser field. Exail now counts in its portfolio 10 different references of space grade fibers with a guaranteed “Radiation Induced Attenuation” (RIA). New hardening techniques identified, in particular on the occasion of a research collaboration with the French Space Agency (CNES), have also opened horizons for applications in radiation sensing (radiation dosimetry), useful in space (LUMINA project) and in nuclear power plants.

“With the radiation resistant fiber and the modulator for the temporal shaping, you can actually consider that Exail is on the right track to deliver two key components to the main high-energy laser facilities in the world. It shows the company can deliver cutting-edge technology for the high-energy laser field.” Nicolas Beck, Research Engineer at CEA-LMJ