- Photonics & Space

LULI2000 facility powered by iXblue ModBox Front-End

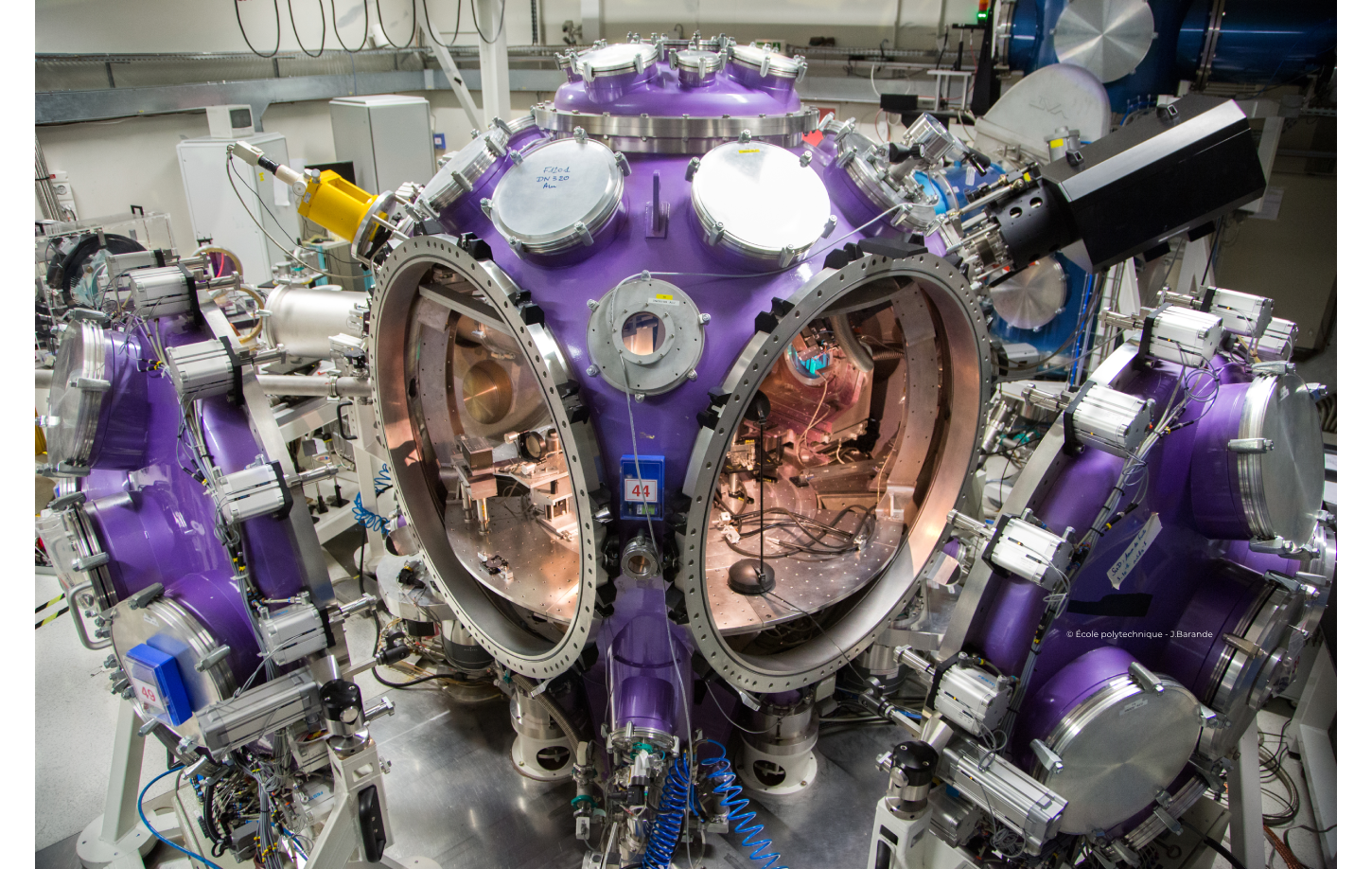

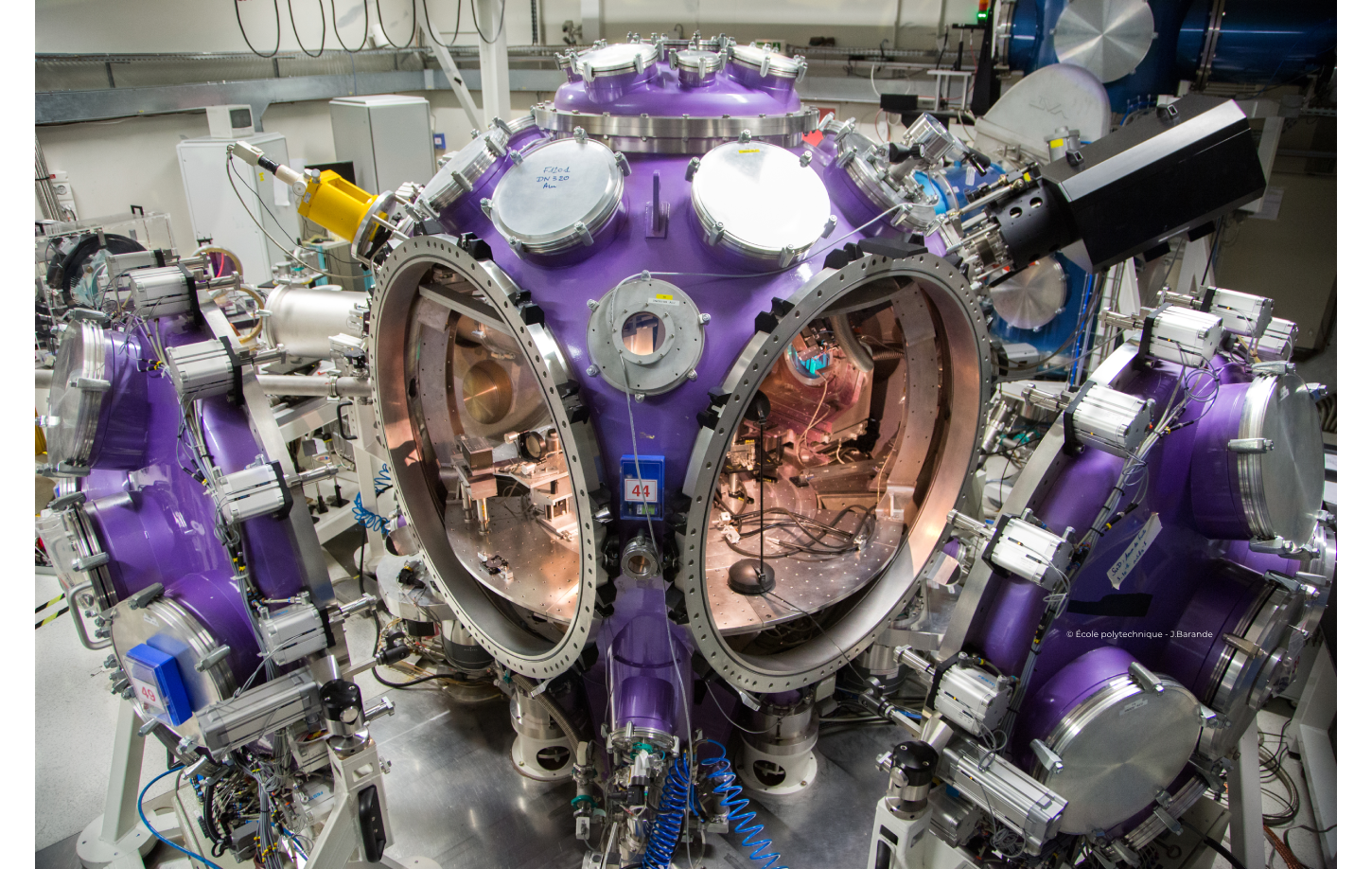

LULI2000 is a high-power laser system dedicated to scientific research. It is hosted since the early 2000’s in Paris-Saclay, in France, at the Laboratory for the Users of Intense Lasers (LULI), a joint research unit of Ecole Polytechnique, CNRS, CEA and Sorbonne Université. The facility delivers 4 chains of high-energy laser beams obtained after focusing onto tiny focal spots (up to 200 μm in diameter). The interaction with small targets produces very hot plasmas, up to many hundred million degrees, high densities and high pressures. Depending on the laser and target parameters, these laser-generated plasmas may be compared to stars or planet interiors.

The main research topics concern laser inertial fusion and all its physical components, fundamental physics of hot and dense plasmas and its applications in astrophysics and geophysics, or the physics and processing of materials. LULI2000 also helps to prepare at best the experimental campaigns on very large facilities (like Laser MegaJoule in France, and XFEL in Germany), by validating concepts, testing diagnostics, training the technical staff, etc.

In 2010, the LULI2000 facility was totally modernized and gained a lot in capability and reliability, at the instigation of Loïc Meignien, new facility manager. He impelled the modernization of the whole pilot room of the facility and the installation of new fiber laser oscillators on the 3 main laser beams enabling different pulse profile shaping. He initiated the collaboration with iXblue around the development of the ModBox solution, leading to a versatile facility, where the temporal shaping and timing could be changed and programmed in advance. “It generated an increase of scientific outputs, in astrophysics for example.” according to Loïc Meignien.

“Since the first prototype of the ModBox that we have developed 10 years ago with iXblue, we have had a very fruitful partnership. We have continously exchanged together to obtain the best solution for our facility. It was eventually supplied by iXblue to other French and European high-energy laser facilities. Today we have reached the 4th generation of ModBox installed at LULI2000”.

He points out another advantage: “iXblue ModBox solutions are based on the most up-to-date telecom components, when other large high-energy laser facilities still use technologies from the late 90’s. Surely, LULI2000 is equipped with one of the best ModBox solution available today, and it is even totally unique regarding the number of various laser beams available simultaneously.”

iXblue Optical Pulse Shaper & Laser Front End

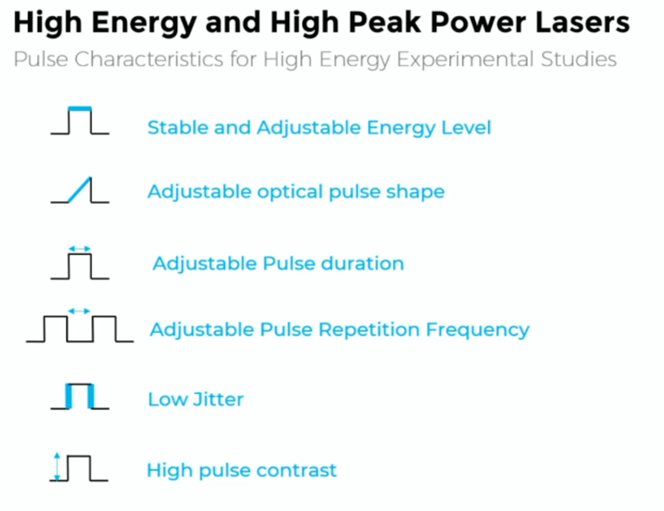

Based on its unique in-house technologies, iXblue has developed the ModBox-FrontEnd, a turnkey system ideal for optical pulse shaping. iXblue has built up a strong experience in such systems and success fully installed them in many research laboratories over the world, and in industrial companies. With these ModBoxes, iXblue offers the most comprehensive portfolio of versatile sub-nanosecond resolution laser pulse shaping based on LiNbO3 modulator design, company flagship expertise.

The ModBox-FrontEnd is challenging the state of the art of temporal pulse shaping performance, as Alexandre Soujaeff, ModBox Business Engineer describes it: “With the ModBox FE we are able to generate laser pulses with any kind of temporal shape. And compared with a simple modulation solution, an integrated ModBox solution offers unique performance in term of contrast and stability”.

Laser Nuclear Fusion

Last year, the NIF laboratory announced a breakthrough in nuclear fusion with a record generation of energy in a laser induced nuclear fusion reaction. More than a GigaWatt of fusion power was generated for 100 ps in a hot-spot the size of a human hair. In parallel, there are a couple of startups offering to develop power plants based on innovative concepts using laser as a driver for nuclear fusion (not to be confused with inertial fusion technology like the ITER project that uses a Tokamak technology). In both cases, the goal is to use the intensity of several laser beam pulses converging on a tiny nuclear fuel target.

For nuclear fusion with lasers, the temporal pulse shaping is crucial as the energy involved is huge, and thus any deviation in the laser pulse shape and contrast can have a disastrous impact on the experiment. iXblue ModBox is a solution totally suited to this field thanks to its ability to control the temporal profile and timing of all the laser beams focused on target toward the fusion ignition.

Laser and particle beams for “Big Science”

Another field of application are the lasers used in research to explore interactions of photons with beam of particles, or to control or generate beams of fundamental particles like electrons/protons or X-ray radiation. For this field of fundamental science, a ModBox is convenient as it can also create tailored optical pulse burst on demand. “For example, impulsion from few tens of picoseconds to hundreds of ns of a specific shape can be generated at a repetition rate up to 100 kHz, with a very high precision and flexibility. This kind of “burst mode” is convenient for linear particles accelerator which are set with a specific tempo.” points out Alexandre S.

Pumping laser for very powerful laser

An example of very powerful laser facility is the L4 ATON laser system at ELI Beamlines infrastructure located near Prague in Czech Republic. It is designed to reach an exceptional multi-petawatt laser peak power of 10 PW. It will allow the production of particle beams and radiation with unique parameters, allowing the exploration of new research’s fields from relativistic physics to vacuum physics.

To achieve these results, the L4 laser is based on mixed glass and OPCPA (Optical Parametric Chrip Pulse Amplification) technologies, including iXblue ModBox. The temporal shaping is mandatory in this application to offer flexibility and precision in the manipulation of the laser optical spectrum. The accurate temporal control allowed by the ModBox guarantees a high peak power at the output of the L4 laser.

Shot peening in industry

High-power lasers with advanced pulse shaping are used in an industrial application: the shot peening, also known as shot blasting. It is a process used to strengthen metallic parts of complex structures used in harsh environment (i.e. in aeronautics), to prevent fatigue, stress and corrosion failures for a longer product lifetime.

For this type of industrial application, iXblue ModBox solutions offer a very controlled and repeatable solution to shape the laser beam. iXblue is already supplying the leading companies of this high-end industrial market.

From components to the last version of iXblue ModBox-FrontEnd

Today, the ModBox-FrontEnd offers the ultimate performance for the end user by integrating screened and selected components that are controlled by a dedicated software interface for intuitive (and gradual) control to provide reliable and stable operation. Continuous product development is central to the company’s activities. This focus on innovation has enabled the company to establish and maintain a leading position in the strategic laser market.

iXblue masters the 3 key components needed for optical pulse shaping application: the Electro-Optical Modulator (EOM) based on lithium niobate technology, the high speed and high voltage linear driver for EOM modulators and the modulator bias control (MBC) board. Each new customer request and each new challenge has led to an improvement of iXblue expertise, leading to the most recent products currently in the company portfolio. In the ModBox Front-End market for optical pulse shaping, iXblue really offers the unique solution currently available. Each ModBox can be customized to the customer needs, thanks to our standardized building blocks.