- Photonics & Space

New erbium/ytterbium doped fibers for high-power laser

With its extensive know-how in designing and manufacturing erbium/ytterbium (Er/Yb) doped optical fibers, Exail can address specific requirements for the assembly of high-power fiber amplifiers and lasers, for LIDAR or space telecommunication applications.

High-power lasers are used today as LIDAR laser sources dedicated to autonomous vehicles (in pulsed regime) for the mapping of their environment, or to equip ground-base stations with high-power amplifiers for ground to space optical communication links (in quasi continuous-wave regime). Exail’s process techniques for the manufacturing of specialty fibers keep being optimized to enable high-power laser systems with higher efficiency and lower 1μm parasitic optical noise.

With high power range, the limited quantum efficiency leads to a significant heat increase in Er/Yb fibers. The temperature of acrylate coating, used in most Er/Yb fibers, is limited to 85°C. Managing the pumping signal interaction with the fiber coating is thus an important challenge. In the environment of a compact LIDAR laser source embedded in an autonomous vehicle, the external heat, which can rise up to more than 100°C, is an additional challenge.

In 2023, Exail has added new references of Er/Yb doped fibers to its portfolio, offering new solutions to ensure a high-power laser transmission even under high temperatures, with larger core and polarization maintaining capability. “Those new references can address the requirements for the assembly of lasers with higher peak energy, meaning laser systems with a larger range.” Explains Arnaud Laurent, Specialty fiber product line manager at Exail.

Those developments benefit from the recognized trademark of Exail Er/Yb co-doped fibers developed over the past 10 years.

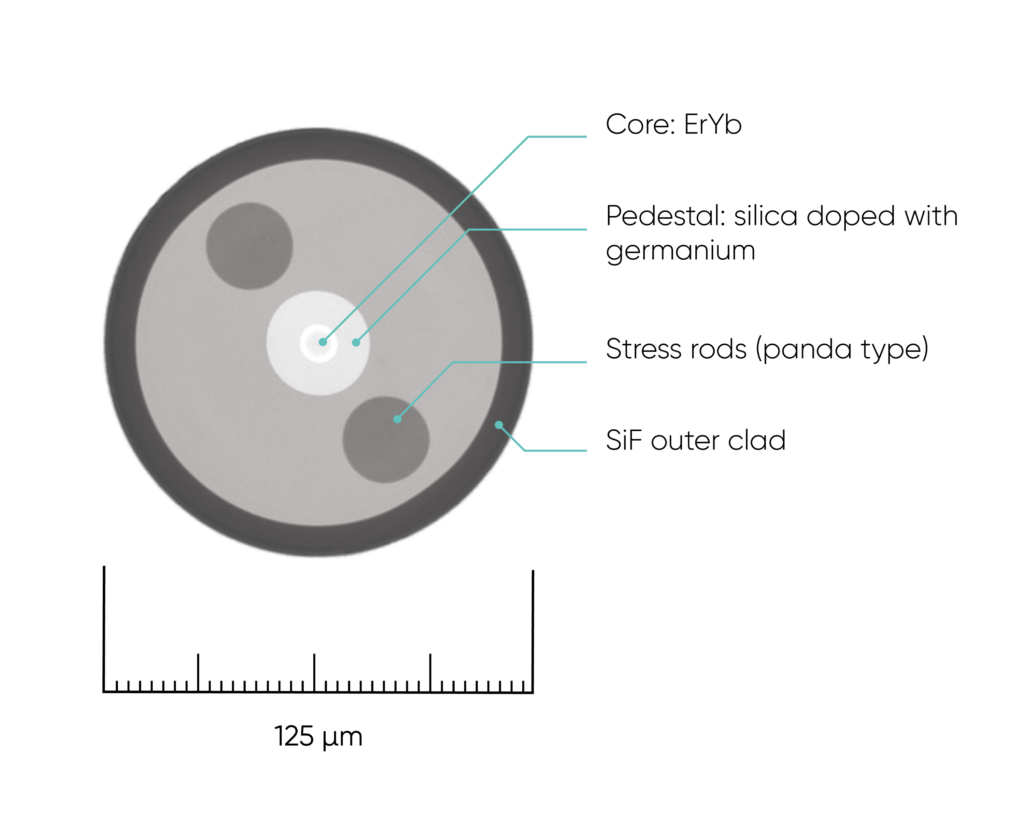

Exail already offers Er/Yb doped fibers with a High Temperature dual layer acrylate Coating (HTC), used to increase the long-term operational temperature range up to 125°C. Those are available with polarization maintaining design. Exail also recently developed the All-Glass Er/Yb, to avoid any issue regarding the interaction of the pumping laser with the fiber coating, where the Er/Yb core is surrounded by a double (or even triple) cladding. Between the two claddings is a Fluorine doped Silica (SiF) material with lower index, meaning that the laser beam interacts only with glass within the fiber, making it very reliable and optically insensitive to acrylate damage. The most recent improvements in the manufacturing process have enabled to develop Er/Yb doped fibers with larger core and higher reliability, which is key for the implementation of a compact LIDAR laser source for automotive environments.

The Double Clad Er/Yb doped fiber with a core of 10 μm is now offered as a single mode fiber with a Mode Field Diameter (MFD) of 11.5 μm, for an external diameter of 130 μm. It exists with High Temperature acrylate coating. It has been designed for applications in LIDAR laser sources requiring high power. And the All-Glass Er/Yb doped fiber is now available with a core of 12 μm (5 μm or 9 μm in previous versions), for an external diameter of 125 μm. It also has a Polarization Maintaining capability. The core composition has been carefully selected to provide high efficiency and long-term reliability which are key advantages for harsh environments, with reduced system cooling requirements.

“With those updates, the new Er/Yb All-Glass PM fiber is unique with its 12 μm singlemode core design. This new reference of PM Er/Yb all-glass allows the LIDAR manufacturers to develop systems with higher pulse energy and thus a larger range. It will be possible to recover more data from a larger range around the LIDAR” according to Arnaud Laurent.

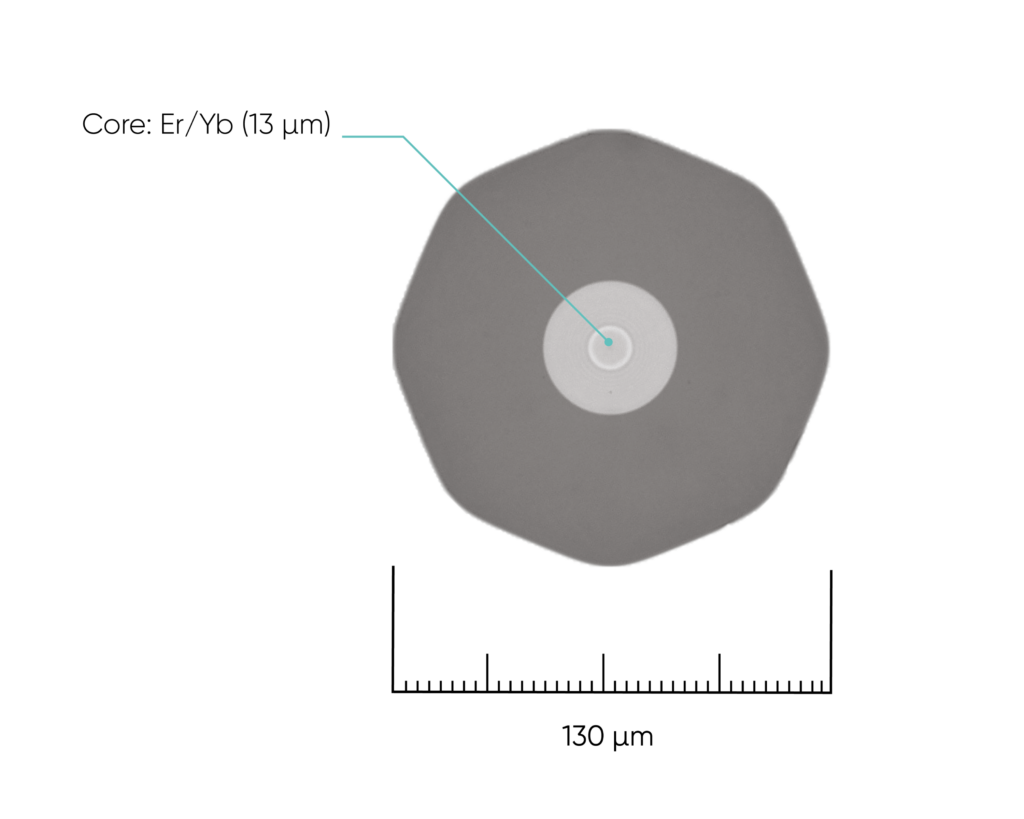

High-power continuous-wave fiber lasers, for example for ground to space optical communication links, rely on fiber with large core diameter, where most of the light power is transmitted. Fibers currently available on the market for these applications have large core (25 μm) but also a large external diameter (250 μm in total). They are difficult to cleave and splice, more sensitive to bending and thus difficult to manipulate and assemble. Matching components are also more difficult to develop and more expensive. Fibers with smaller core exist for high-power amplifier application, but they are multimode which can create power instabilities in a compact system, and they also present reduced Mode Field Diameter (MFD) at 1.55 μm.

With its industrial capabilities and state-of-the-art technology, Exail could develop a monomode fiber with a large core: the Er/Yb Double Clad doped fibers with a core of 13 μm. It is a single mode fiber at 1.5 μm, with a large MFD (13.5 μm-15.5 μm), High Temperature and a low 1 μm parasitic emission (thanks to a specific design of the matrix). It is an ideal compromise among the existing products for high-power CW fiber laser.

The most recent tests show an excellent behavior of the fiber at 40 W in continuous mode over several days without any power loss. The matching passive fibers developed by Exail, both single clad and double clad are

available and in stock. Moreover, the fiber is easy to handle, bend and splice. A version with Polarization Maintaining design will be available soon.

|

New Er/Yb doped fibers references available in Exail portfolio

All-Glass, 9 or 12 μm (core size), with High Temperature acrylate Coating (HTC) for LIDAR applications:

Double Clad, 10 or 13 μm (core size), for high-power amplifier (HPA) in ground-based stations for optical space telecommunication:

|